As a leading manufacturer of cosmetic tube packaging, our factory is committed to providing high-quality and customized solutions to meet the unique requirements of customers in the beauty industry.In this article, we outline the process of designing cosmetic tubes to ensure that every product we supply meets our customers’ exact specifications.

Development concept: The customization process begins with a thorough understanding of the client’s vision and requirements.Our design team conducts in-depth research on target markets, competitors and emerging trends to create innovative concepts of cosmetic tubes.We work closely with our clients to ensure their brand identity and product essence are reflected in the design.

Material selection: Once the concept is approved, we move on to selecting the right material for the cosmetic tube. Our team considers factors such as compatibility with different product formulations, durability and aesthetics. We offer a wide range of materials including PE/PCR/Sugar Cane/Aluminum Plastic/Wheat Straw, ensuring that the final product meets the required quality standards.

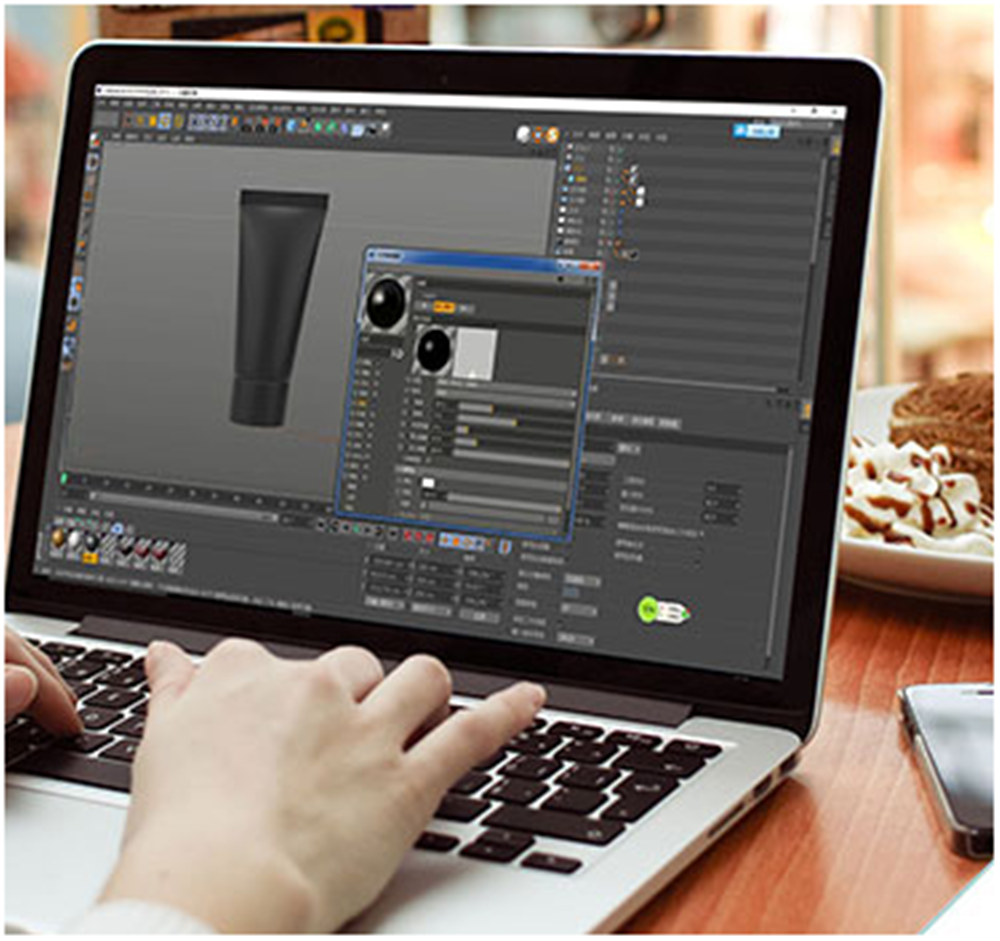

Technical Design: Our engineers use advanced CAD software to create detailed technical drawings of cosmetic tubes.These drawings include exact specifications, dimensions and features such as airless pump mechanisms and removable covers.The technical design ensures the functionality and smooth operation of cosmetic tube packaging.

Prototyping: To ensure customer satisfaction, we provide prototyping services to bring designs into reality.Our factory utilizes advanced 3D printing technology to create physical samples of cosmetic tubes.This prototype allows our customers to visualize and evaluate the design, ensuring it meets their expectations before going into mass production.

Colors and Trims: We know that visual appeal plays a vital role in cosmetic packaging. Customers can choose from a variety of colour, finishes and decorating techniques to enhance their brand image.Be it screen printing, hot stamping or matte/glossy finishes, our factory can accommodate every kind of custom request.

Quality assurance: We carry out strict quality control inspections on the cosmetic tubes before starting mass production.These tests ensure that packaging materials meet industry standards for safety, durability and functionality.Our commitment to quality ensures that our customers receive products that not only look great, but perform flawlessly.

Packing and delivery: We provide comprehensive packaging solutions to ensure the safe transportation of our cosmetic tubes products. Cosmetic tubes are carefully packaged to prevent damage during shipping. Our factories work closely with reliable transportation partners to ensure timely and safe delivery of finished products to customers’ designated locations.

All in all, the cosmetic tube design process in our factory involves comprehensive and meticulous steps from concept development to mass production. Our experienced team, advanced technology and commitment to customization ensure our clients receive superior cosmetic tube packaging solutions that enhance their brand image and drive their business success.

Post time: Jul-10-2023